Additive

Mazak has been a pioneer in developing hybrid technology that combines the processes of additive and subtractive processes in a single machine tool. This unique approach enables the production of complex parts with high accuracy and precision.

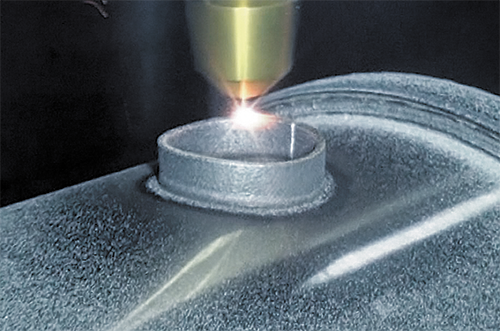

The hybrid additive process uses either electric arc wire or powdered metal in combination with a fiber laser to build up material in specific areas of a part in the same machine tool that is then used to mill away excess material to achieve the desired shape and surface finish.

Action Machinery

Action Machinery