In the heart of structural steel and fabrication sectors, beam processing remains an indispensable procedure, forming the bedrock of myriad large-scale projects. The modern-day wave of technological advancements has created a plethora of machining equipment, each tailored to enhance precision, mitigate manual labor, and amplify productivity.

Two big names, Peddinghaus and Ocean Machinery, have thrown their hats in the ring with machines that have changed the game in beam processing. This article dives deeper into their offerings, eyeing multi-spindle and single-spindle drill lines, alongside other noteworthy machines like the Liberator and PeddiWriter.

Understanding Beam Processing

Before we dive into the nitty-gritty, let’s get a grasp on the essence of beam processing. This term is an umbrella encapsulating numerous operations conducted on structural steel beams to prime them for assembly or installation in construction and other industrial behemoths. It involves cutting, drilling, marking, and occasionally welding or surface treatment to ensure the beams dovetail with the precise specifications of a particular project.

The goal of beam processing is to enable a seamless assembly, ensuring the robustness and integrity of the final structure. Modern machining equipment has significantly streamlined this process, bringing to the fore a higher degree of accuracy, diminished waste, and quicker delivery timelines.

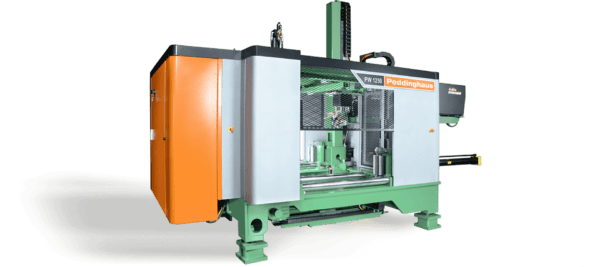

Peddinghaus – Multi-Spindle Drill Lines

Peddinghaus’s stronghold in the market is significantly bolstered by its multi-spindle drill lines. These machines are synonymous with substantial throughput in beam processing, courtesy of their simultaneous drilling capability which starkly trims down processing time vis-à-vis single-spindle alternatives. Their rugged design, tailored for high-production environments, is a pledge of reliability intertwined with precision.

The automation features embedded within Peddinghaus multi-spindle drill lines simplify the beam processing workflow, catapulting productivity to new heights. This blend of robustness, precision, and automated prowess makes beam processing a seamless endeavor.

Ocean Machinery – Single Spindle CNC Drills

On the flip side, Ocean Machinery’s single spindle CNC drills have carved a niche, especially among small to medium fabricators. Despite being single-spindle machines, the precision and efficiency they champion are commendable. These machines are a boon for workshops in need of a compact, easy-to-manage, and precise beam processing solution.

The CNC technology imbued in these machines facilitates high-precision drilling, ensuring each beam is meticulously processed to exact specifications, embodying Ocean Machinery’s ethos of quality without compromise.

Ocean Machinery – Liberator

Ocean Machinery’s prowess extends with the Liberator, an epitome of user-friendliness, efficiency, and quality output in beam processing. Its intuitive interface is a magnet for operators, drastically tapering the learning curve.

The Liberator’s avant-garde technology is a guarantee that each processed beam meets the stringent quality benchmarks requisite in modern construction ventures. This machine is a manifest of how user-friendliness and high-quality output are not mutually exclusive but can be harmonized to optimize beam processing operations.

Peddinghaus – PeddiWriter

The PeddiWriter from Peddinghaus is a trailblazer aimed at streamlining the layout marking process in beam processing. By automating the marking process, this machine is a boon in reducing manual labor and minimizing errors, thus accelerating the beam processing workflow.

The PeddiWriter is a nod to Peddinghaus’ allegiance to innovative solutions, drastically speeding up a traditionally labor-intensive and error-prone phase, and enabling fabricators to meet stringent deadlines while maintaining a pinnacle of accuracy.

Conclusion

Both Peddinghaus and Ocean Machinery unfold a spectrum of machines addressing diverse needs within the beam processing sector. Whether it’s the high throughput multi-spindle drill lines from Peddinghaus, the precision single-spindle CNC drills from Ocean Machinery, the user-friendly Liberator, or the innovative PeddiWriter, the choice of the right machine hinges on the specific requisites of a fabricator. These machines are emblematic of the modernization and optimization sweeping across the beam processing workflow, paving the path for more efficient and precise fabrication processes.

Action Machinery

Action Machinery