In the evolving world of hand rail production, a key determinant of quality, efficiency, and reliability lies in the machine used. Hand rail processing machines are specialized equipment designed specifically to cut, design, and bend handrails with superior accuracy. As such, selecting the right machine for your needs is crucial.

Among the myriad options available, three machines hold a significant position in the market: the Automated Layout Technology Lightning Rail, the Bend Tech Dragon A400, and the Tube Bending machine. In this article, we dive deep into the unique features of these machines to guide you in making an informed decision.

Automated Layout Technology Lightning Rail

One of the leading names in the hand rail processing domain, the Lightning Rail offers a blend of speed, accuracy, and user-friendliness.

Key Features:

- Precision and Speed: With this machine, compromise is not an option. It combines rapid processing speed with detailed accuracy, ensuring every hand rail meets the highest standards.

- User-friendly Design: Its intuitive interface makes it approachable, even for those new to the industry, ensuring minimal training time.

Ideal for: Businesses that tackle large-scale projects or custom jobs, where speed and precision are paramount. If efficiency is your priority, the Lightning Rail is worth considering.

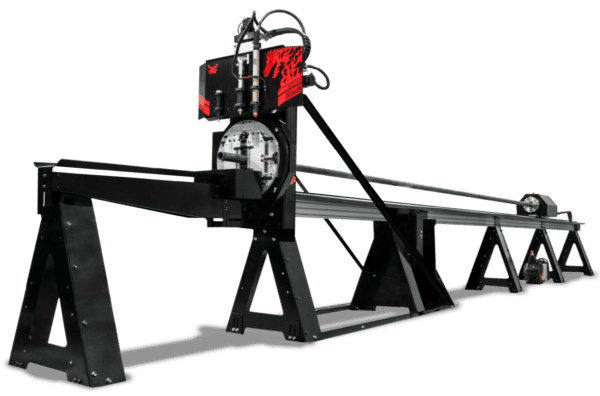

Bend Tech Dragon A400

A powerhouse in hand rail processing, the Dragon A400 is known for its dual functionality and integrated features.

Key Features:

- Dual Functionality: Beyond just cutting, it expertly bends handrails, offering an all-in-one solution.

- Innovative Software: Its proprietary software ensures seamless design and processing, effectively reducing errors.

- Space-Efficient: Its compact nature means it doesn’t monopolize workshop space, making it perfect for setups with spatial constraints.

Ideal for: Businesses that prefer a comprehensive approach to hand rail processing. If you’re aiming to minimize multiple machine dependencies, the Dragon A400 offers a streamlined solution.

Tube Bending Machine

For those seeking versatility and consistency, the Tube Bending machine stands out as a compelling choice.

Key Features:

- Adaptable Design: Designed to work with varied materials and diameters, this machine is perfect for businesses with diverse project needs.

- Unwavering Consistency: Every bend, irrespective of the material, is consistent, ensuring the structural integrity of the hand rails.

- Robust Build: Its durability ensures prolonged use without frequent maintenance, translating to a cost-effective solution in the long run.

Ideal for: Companies with varied hand rail designs and material needs. If your operations demand flexibility without compromising quality, the Tube Bending machine is your answer.

Choosing the right Hand Rail Processing Machine

Choosing the right hand rail processing machine goes beyond just the initial investment. It’s a decision that echoes in the quality of your products, the efficiency of your operations, and ultimately, the trust you garner from your clientele. While the Automated Layout Technology Lightning Rail champions speed and precision, the Bend Tech Dragon A400 simplifies the process with its dual functionality, and the Tube Bending machine offers unparalleled versatility.

Your decision should hinge on your business’s specific needs. Understand your volume of production, the diversity of designs you cater to, and the space constraints of your workshop. Moreover, consider the machine’s longevity, potential maintenance needs, and adaptability to technological advancements.

In essence, the right hand rail processing machine is one that aligns seamlessly with your business objectives, guarantees the safety of the end product, and fortifies your reputation in the industry. Choose wisely, as this machine will be an instrumental partner in your hand rail production journey.

Action Machinery

Action Machinery